Centrifugal Pumps

Moreover, in compliance with the localization project since the IVth quarter of 2020 the company is ready to assemble centrifugal pumps according to the specifications agreed with customers.

AMCOR specializes in the implementation of engineering projects, selection of industrial equipment in accordance with specific needs and supply of industrial equipment.

Centrifugal pumps are characterized by simplicity of design, provide high performance and pressure, can be used in applications that require transportation of liquid and gaseous media containing impurities. They are well proven in operating conditions with permanent high loads and in complex operation modes. Centrifugal pumps are particularly effective for pumping of large fluid volumes.

For the needs of domestic enterprises our company mainly supplies overhung, between bearing and vertical centrifugal pumps.

Most models of pumps fully comply with API 610 (API – American Petroleum Institute), which establishes the basic requirements for centrifugal units.

Design of pumps manufactured according to API 610 ensures reliable, long-term and safe operation in hazardous conditions of the oil, oil refining, petrochemical and gas industries.

API 610 standard regulates the strict requirements in terms of service life and the overhaul period, pressure tests of the pump casing, design features of the impeller, shaft, bearings, base plate and other important components and parts.

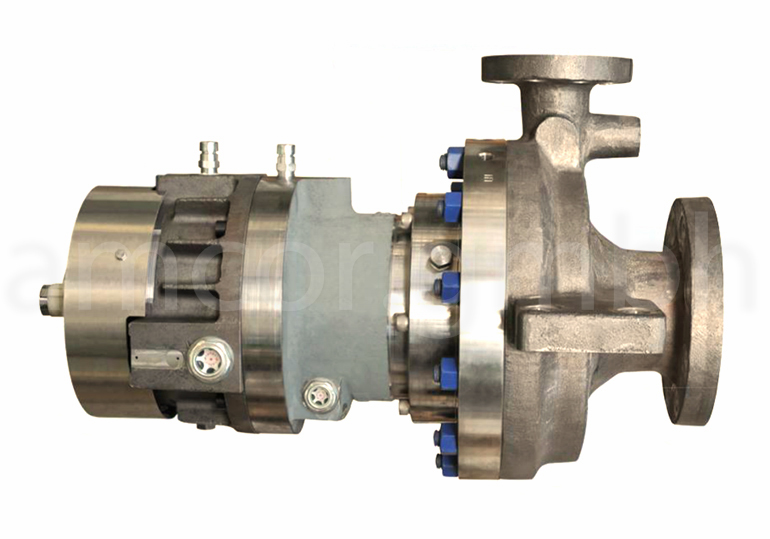

A distinctive feature of the overhung units is that the impeller is mounted on the end of the shaft. Their advantages include compact size, ease of maintenance, and applicability in severe operating conditions.

Overhung centrifugal pumps are available in the following versions:

- Horizontal with shaft support along the central axis. Radially split pump case.

- Horizontal with magnetic drive.

- Vertical in-line pumps.

- Vertical. The impeller is mounted on the motor shaft.

- Vertical with single and double suction.

Overhung units can provide capacities: up to 6,000 m3/hour, head: up to 380 m, working temperature: from -150 to +450 °C, pressure: up to 210 bar, rotation speed: up to 4,000 rpm.

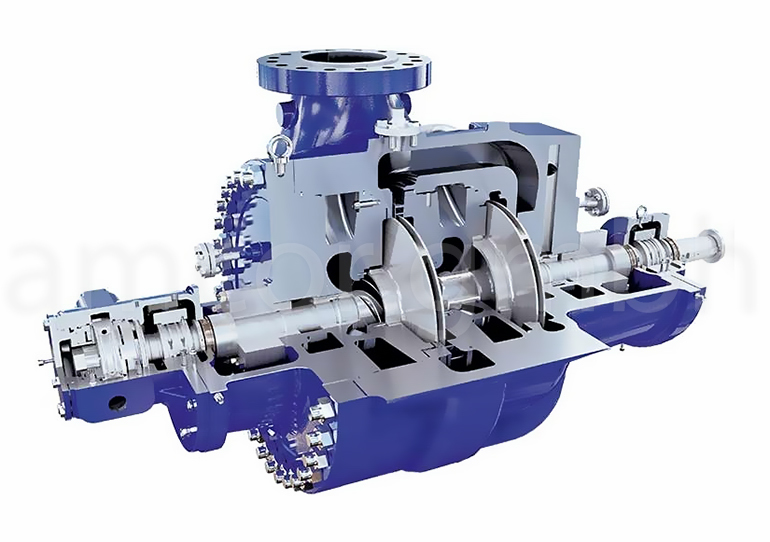

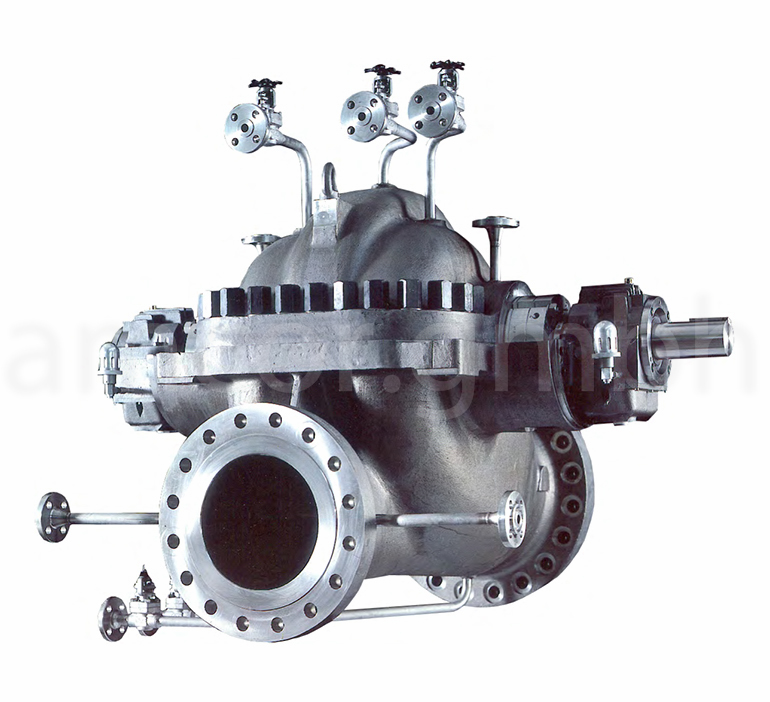

Most versions of the between bearing pumps have modular design. This meets the latest trends in pump engineering. Modular design helps to expand the application range, provides the possibility to replace a number of assemblies and their re-use. The case with nozzles is manufactured as one block. The best sealing devices are used, which perfectly protect against undesirable inclusions.

Between bearing pumps are available in the following versions:

- Horizontal with single and double suction. Radially split case.

- Horizontal with double suction. Axially split case.

- Multistage with horizontal central axis, diffuser, single and double suction. Axially split pump case. Up to 13 stages.

- Multistage with horizontal central axis, diffuser, single and double suction. The pump is barrel-shaped with a radially split case. Up to 14 stages.

Between bearing pumps can provide capacities: up to 18,000 m3/hour, head: up to 3600 m, working temperature: from -30 to +455 °C, pressure: up to 350 bar, rotational speed: up to 7,000 rpm.

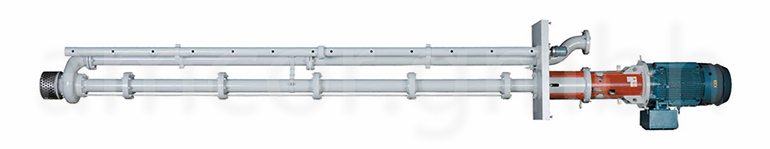

Vertical centrifugal units have closed type of impeller, which provides optimal balance and reduction of axial loads.

They are available in the following versions:

- Single stage with a side discharge column.

- Multistage. Equipped with a diffuser. Options: drainage and two-case. Up to 14 stages.

- Multistage. Equipped with a diffuser or a double volute. Options: drainage and two-case. Up to 5 stages.

Vertical pumps can provide capacities: up 18,000 m3/hour, head: up to 2000 m, working temperature: from -150 to +400 °C, pressure: up to 210 bar, rotation speed: up to 3600 rpm.

Projects implemented by our company fully satisfy the needs of the customer, ensure successful modernization and increase the operational efficiency of an industrial facility.