Plunger Pumps

AMCOR provides engineering services and supplies a wide range of pumping equipment, including plunger pumps and systems, helping customers to implement ambitious projects and achieve successful results in their business.

Plunger pumps are reliable, robust, high-performance, energy-efficient, compact units that are widely used in high-pressure applications.

In the chemical and petrochemical industries plunger pumps are parts of the ethylene, polyethylene, melamine, methanol, resins and alcohols plants. At mineral fertilizer plants plunger pumps are used as ammonia and carbamate pumps.

In the oil and gas industry plunger pumps are used in gas processing, gas regeneration and storage; in units for pumping of hydrate formation inhibitors, liquefied carbon dioxide and water into oil wells; systems for pumping of monoethylene glycol; units for pressure tests of pipelines and equipment for oil pumping stations.

At oil refineries plunger pumps are applied in the processes of dewaxing, hydrocracking, visbreaking, hydrofinishing, hydrotreating, can be used for pumping of hydrocarbon condensate, off-specs oil, bitumen and heavy oils.

High competition, based on the growth of productivity and efficiency of technological processes, favors the use of equipment, which technical and economic indices provide the required production level today and will provide it in the near future.

Our specialists have the proper experience and knowledge to choose pumping equipment that fully satisfies the operating conditions and solve all problems of modernization of existing facility or construction of a new one.

Among plunger pumps, which are widespread in a number of industrial sectors, including the previously mentioned, the following groups of equipment can be single out:

- Reciprocating pumps.

- Technological diaphragm pumps.

- Metering pumps.

- Pumping systems.

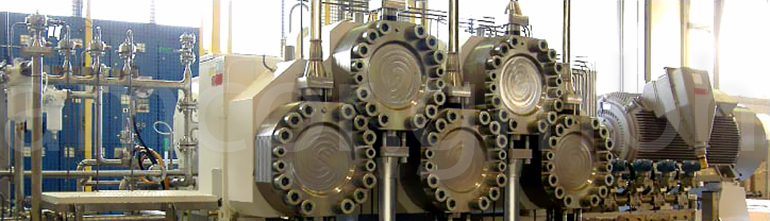

The first group is represented by reciprocating pumps with three-, five-and seven cylinders. This group includes middle-power pumps (up to 600 kW), high-power pumps (up to 2500 kW), as well as steam-driven units.

Pumps with power up to 600 kW, as a rule, have three cylinders. At the same time, there are several models with five and seven cylinders. All of them are highly reliable, do not require additional lubrication systems, durable, their design provides simple and easy maintenance.

Models with power up to 2500 kW are designed for applications where they can be used for a long time at high loads and with extended service intervals. These are three-, five-and seven-cylinder horizontal pumps. Due to the smaller static and dynamic loads, five- and seven-cylinder pumps are more preferable than three-cylinder ones. They have less wear parts, so their overall life time and reliability is higher.

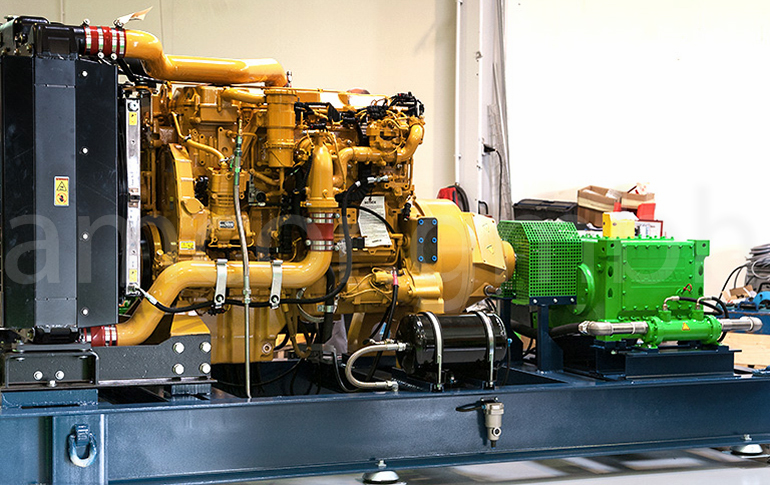

In steam driven pumps, under the action of the working fluid on the piston, all power is transmitted directly to the plunger of the hydraulic part. Most often steam is used as a working medium, less often – gas or air. Regulation of pump speed can be carried out manually and automatically. These are flexible pumps that are most commonly used for pumping viscous and high-temperature fluids.

The technological diaphragm pumps of the second group are a good choice for the handling of various explosive liquids, as there is no contact of the working fluid with the atmosphere and other pump components. The working fluid is moved with the diaphragm, and the latter is affected by the intermediate fluid. Such pumps have a robust and safe design with a small size and weight.

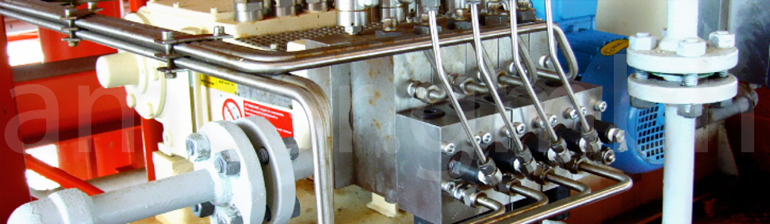

The third group covers metering plunger, diaphragm and plunger pumps with several hydraulic parts. All models have the capability to control the flow in the range 0 ... 100% with an error of less than 1%.

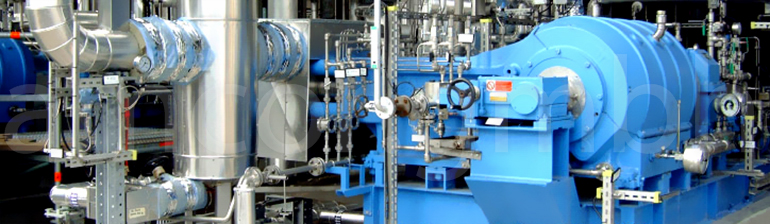

Pump systems of the fourth group are offered as complete packaged units, and all the equipment usually is arranged on one common frame. Such systems are a comprehensive solution for a wide range of applications and are designed to meet certain working conditions, previously specified by the client.

For the successful implementation of projects in the chemical and petrochemical, oil and gas, and oil and gas processing industries, high-quality, reliable, well-thought-out equipment is required. In practice, custom-made equipment is the best option for this purpose.

Acting as an EPC contractor, AMCOR, guided by the customer requirements specification, is ready to provide a technically competent solution with an optimal configuration of pumping equipment, which fully satisfies the specific operating conditions.